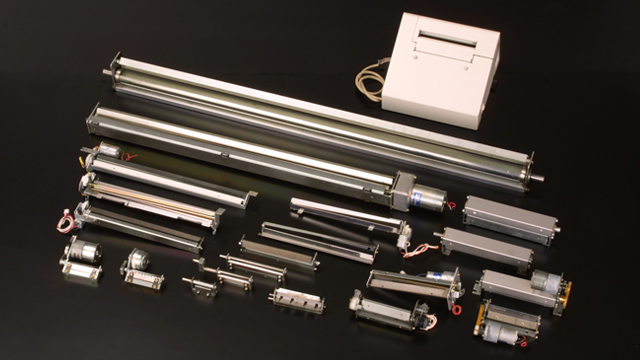

Cutter unit[by cutting method]

Cutter units are classified into the following three main types.

Rotary cutter unit

|

Characteristics

This cutter is structured by combining a rotary blade and a stationary blade.

There are a V type and W type. With the V type, the rotary blade makes one rotation when cutting, and with the W type, the rotary blade makes a reciprocating motion (swings) when cutting. and V type can be cut while moving a sheet.

Moreover, in order to make a sheet easy to set, there is also a type which separated the rotary blade and the stationary blade.

According to the specification and the operating condition of a sheet, there is lineup of the material of blade, form, and component formation.

Slide cutter unit

|

Characteristics

Cutter combines reciprocating movable blade with a fixed blade.

The movable blade is roughly divided into V-shaped and linear-shaped types, and the V-shaped type is further divided into three types: full cut (full length cut), partial cut (leaving the center uncut), and full/partial switching mechanism. To cut sets of sheets easily, it is also possible to make a separate rotary blade and fixed blade.

The linear-shaped type can cut relatively thick paper, allowing high-grade cutting. In particular, it is suitable for cutting photographic paper, which requires a high-grade cut edge.

Roller cutter unit

|

Characteristics

Compact and lightweight cutter, which can handle a wide range of sizes.

There are two blade structure types. In one structure, the disk blade reciprocates while rotating around a fixed blade. In another structure, two disk blades reciprocate in combination along the frame. Various driving methods using a wire, belt, shaft, etc., are available.

We propose units composed of optimum blades and a driving part according to cutting specifications.