Core Technologies for Creating Trusted Products

|

Proterial Precision relies on various core technologies to create products that earn the trust of customers. They include CAD-applied tooling and precision forming technologies, advanced casting and powdery sintering technologies available for various materials, and highly automated production technologies. Using its proprietary technologies, we offers high-value-added products of the High precision.

Casting Technology

High-quality casting of various types of high-grade special steel is based by our optimum casting conditions for different product shapes and high-level casting technologies that have been accumulated over many years. |

Powdery sintering Technology

Outstanding technology to sinter metal powders enables high precision manufacturing of MIM parts in complex 3-D shapes. The development of new products, parts made of composite materials, is aggressively under way. |

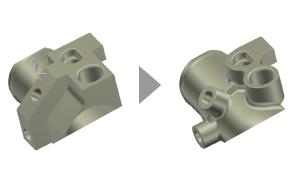

Re-design

Proterial Precision carries out product redesigns to achieve the best quality of products without impairing their functions. Redesigns enable the integration of parts or the eduction of Machining requirements, thereby achieving significant cost reduction. |

Design Technology

Original design by 3D-CAD and cooperation with the customer and the parts maker enable speedy development. |

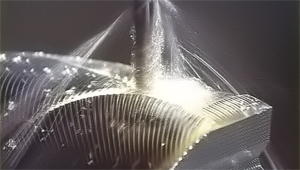

Tooling Technology

CAD/CAM-based speedy and correct design and proprietary tooling structure enable highly accurate reproduction of complicated 3-D shapes. |

Production Technology

Extensive automation of manufacturing

systems to accommodate the different

requirements of precision casting, metal

injection molding, precision forming and |