Characteristics

We support customers’ needs with our high development capabilities and manufacturing technologies.

High level unique manufacturing technologies and metal tooling design capabilities

We manufacture precise sintered compacts and achieve excellent strength and high dimension accuracy by combining unique binder constitutions with optimum manufacturing technologies. We design metal toolings by ourselves, and at the same time, propose weight reduction while maintaining the product strength. We can flexibly respond to customers’ design changes as well as metal tooling maintenance.

Various materials and high development capabilities

We inherit the metallurgical technology of a special steel manufacturer, Proterial, Ltd., and deal with a variety of materials including stainless materials, tool steel, high-speed steel, and super heat-resistant steel. Also, we challenge the development of technologies for manufacturing required materials while receiving technological support.

Furthermore, we have developed new unique technologies such as “magnetic stainless steel” and “junction between MIM products and steel materials”.

We develop various technologies including material technologies, manufacturing technologies, etc.

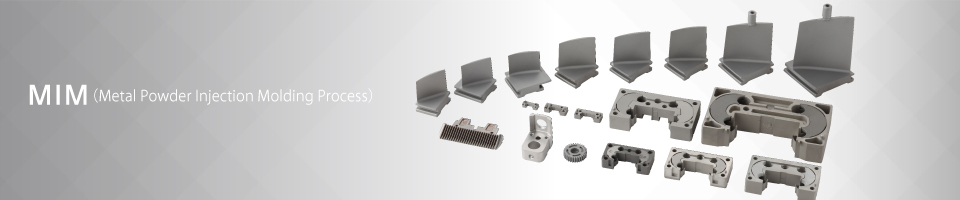

Manufacturing of one of the largest sizes in the MIM industry is possible.

While the MIM is often applied to relatively small products weighing a few grams, we mass-produce products with the highest level of size in the industry. For example, we can manufacture a product with the external size of 120 x 60 x 25 mm and weight of 500 g. (However, we may propose redesign suited to manufacturing.)

Quality assurance cultivated through lost wax

Since we manufacture automobile parts (TS certified), aircraft parts, gas turbine parts, and atomic energy parts using lost wax, we also perform high-grade inspection for MIM. We have three-dimensional measuring equipment, three-dimensional digitizer, X-ray inspection system, penetrant inspection facilities, etc. We can also perform electron microscopic analysis such as property examination for metal surfaces. We respond to quality assurance in accordance with product specifications.