Advice on MIM design

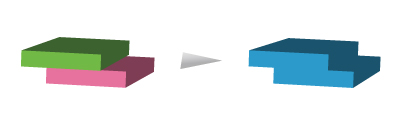

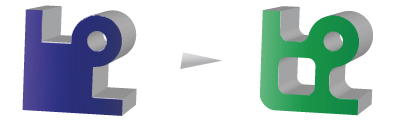

1.Integration

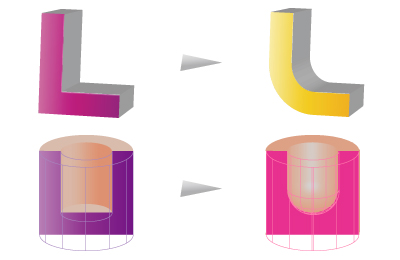

2.Avoiding parts with a thick wall

Because a part with a thick wall is likely to have a molding defect and/or a debinding fault, it is leveled (approximately 1.5 to 2.5 mm) by thinning, ribbing, or other means.

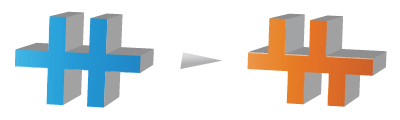

3.Leveling and weight reduction

4.Corner radius

When contracting with low strength, a tensile force is easily generated at the interior angle radius. A small radius is added to disperse the force.

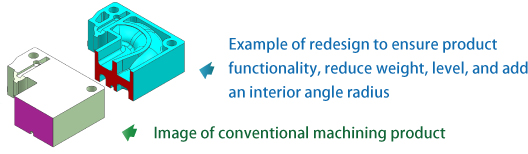

5.Example of weight reduction

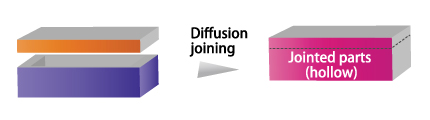

Composite

| Joining the same materials | Achieving thick products for which MIM is difficult (For MIM, it is normally difficult to manufacture a product with a thickness of 5 mm or more in terms of molding and debinding.) |

|---|---|

Achieving undercut products for which metal tooling cannot be molded integrally (example: hollow parts, etc.) |

Example of joining

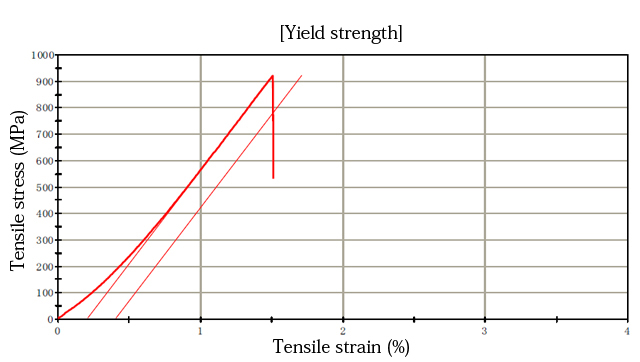

Evaluation of material properties

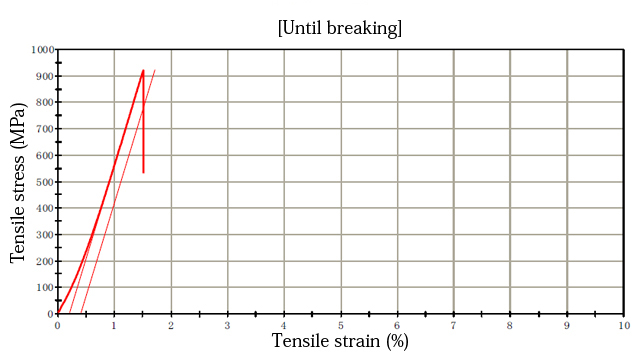

Representative mechanical properties are described in the material list. However, we can perform property evaluations specified by customers

Diameter: 2.524 mm Gauge length: 20.00 mm Test temperature: 23ºC

| Maximum load(kN) | Tensile strength(MPa) | Elongation | Drawing | Break position | |

|---|---|---|---|---|---|

| 1 | 4.619 |

923 |

-100.0 |

100.0 |

C |

Tensile speed: 0.5 mm/min

| Measurement item | Unit | Measured temperature °C | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| 20 | 100 | 200 | 300 | 400 | 500 | 600 | 700 | 800 | ||

| Thermal conductivity | W/cm・K |

0.1242 |

0.1445 |

0.1619 |

0.1790 |

0.1993 |

0.2214 |

0.2469 |

0.2791 |

0.2909 |

| Specific heat | J/g・K |

0.3971 |

0.4367 |

0.4538 |

0.4672 |

0.4855 |

0.5086 |

0.5366 |

0.5761 |

0.5858 |

| Linear expansion coefficient | 10-6/K |

- |

10.93 |

11.59 |

12.07 |

12.49 |

12.91 |

13.40 |

13.87 |

14.20 |

| Young's modulus | GPa |

271.3 |

268.0 |

262.0 |

254.9 |

247.8 |

239.5 |

229.1 |

217.8 |

200.1 |

| Poisson's ratio | - |

0.30 |

0.30 |

0.30 |

0.30 |

0.30 |

0.30 |

0.29 |

0.28 |

0.25 |

| Density | g/c㎥ |

8.862 |

- |

- |

- |

- |

- |

- |

- |

- |

*The above date are shown only for reference, and are not necessarily guaranteed for actual Proterial Precision products.